Announcing a first-time feat, German automaker BMW is putting its vision of the future into practice.

Having recently wrapped a round of humanoid robot testing, the manufacturer is sharing more about an ongoing project, completed in collaboration with U.S.-based robotics company Figure AI. The achievement unfolded in South Carolina at the BMW Group Plant Spartanburg, reaching the automotive sector as innovations from various high-end motor companies continue to improve both the in-car experience and the processes that back the production of powerful, bespoke vehicles.

“The developments in the field of robotics are very promising,” said Milan Nedeljković, a member of the board of management for production at BMW AG, in a statement.

“With an early test operation, we are now determining possible applications for humanoid robots in production,” Mr. Nedeljković said. “We want to accompany this technology from development to industrialization.”

Building the future

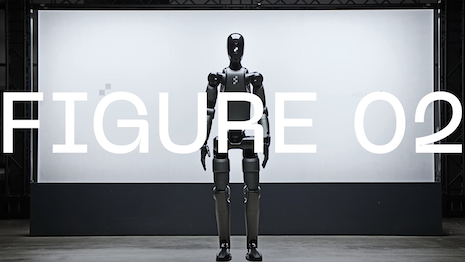

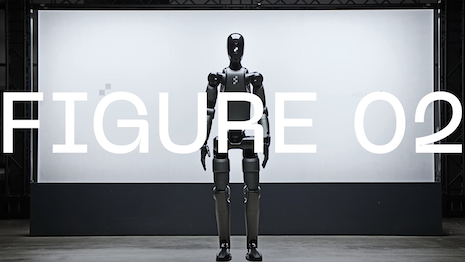

New video content introduces audiences to "Figure 02," an operationally autonomous android powered by artificial intelligence and built by BMW's partner, Figure AI.

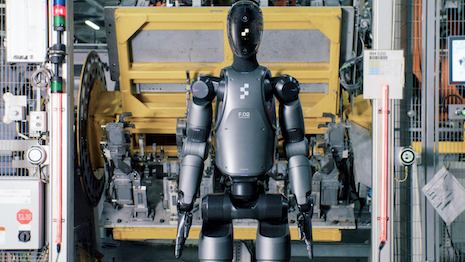

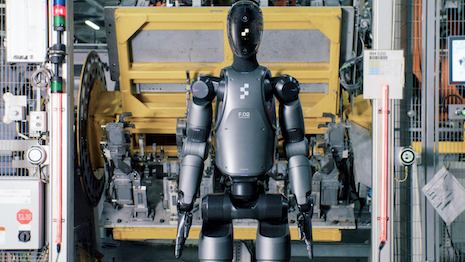

During the brand's multiweek experiment, the temp employee was able to handle tasks considered “ergonomically awkward and tiring” for human team members to finish multiple times throughout a workday, such as inserting sheet metal into mechanical fixtures. Outfitted with six cameras, it also features multiple microphones, sensors, a high-performance battery and hands with 16 degrees of motion.

BMW showcases Figure 02’s current capabilities

The automaker is investigating other potential use cases for advanced tools like these as it seeks to increase the efficiency and sustainability of its factory lines. BMW went public with news of the testing phase this week on Aug. 6, the same day that images of Figure 02 were formally unveiled.

“We are excited to unveil Figure 02, our second-generation humanoid robot, which recently completed successful testing at the BMW Group Plant Spartanburg,” said Brett Adcock, founder and CEO of Figure, in a statement.

“Figure 02 has significant technical advancements, which enable the robot to perform a wide range of complex tasks fully autonomously.”

The automaton can complete tasks with human-equivalent strength and precision. Image credit: BMW

The automaton can complete tasks with human-equivalent strength and precision. Image credit: BMW

According to Figure AI, Figure 02 is the most advanced humanoid robot on the market. BMW will continue to work with the tech company to collect data, optimize software and tweak the training conditions for further trials.

Quantum leap

Other luxury automakers such as Porsche, Jaguar Land Rover and Ferrari are tapping emerging technologies.

Earlier this year, JLR updated its manufacturing capabilities, opening a state-of-the-art software engineering campus in Portland, Oregon (see story) and expanding its use of renewable energy across its operations in the United Kingdom (see story).

Not long after, Porsche began turning to augmented reality platform Apple Vision Pro for hands-on, interactive assembly facility tutorials (see story).

In June, Ferrari opened its first-ever “e-building.” The LEED Platinum-certified structure supplies the automaker’s entire range of powertrains, employing a combination of the latest robotics and machinery to streamline the process. The site will begin running on renewable energy exclusively later this year (see story).

{"ct":"yG6L0R1UbyMkRhj9vu4STQ0hwuJJO5i63vU\/UmHZlcar0EG6rCv4ifjP1fzU2z4iyxVBVAUND1EjEDs2sDNF\/KGor8VHxVdSTrK1khAzQwAIycRk7J1mNpAb0oezsuAvsnPZvhshRIEXdqwTYZV0N3ip594p92lr\/VwM5h2Az+v1d0TTCksqUijl1S6Uah9G430kfq5taTWbM7zXv0ZfgUhcYRuUZXKatFPZ83jQtpBF0R5hq2rvXANMtOHC9GoRPrMIWnazBcxnChWUqq3ke8MNDbygHSc7HFs6WKnIm2q30tqs\/2cZlQrkZ1awhkGOBL++VP\/SEK2CkW14Bw1+GFi2NklryRoE7DXc\/U5TATkqqLThop2bHpPTYz\/WH\/K8CYeq6911PCGxTOVZ1K2VVj0efkPwQ07LYcueO0pepL2eD9RWwf1RBjI9eOuK3p9Lk29Iztvf43FYT8X+2JHi7xXlPuDfc+Z0dvdSeCj3ah1nftfv89ZQATxu6zfKfia1ca3rF9+ecLLEcCQjYk6Ns6pO69EK470ciwg6GYeR\/HjjbmEiLg89hMCA3nnHh\/SL4\/jsPs3BQdzjkSHdVtw4hP\/5NYZ3jx6Rcop+PiTFLv5ijzFWgXxQHZj0ofdWSmIw+g3\/FO1zqyVX8eR2RNNu5AKqZAPdmosnX8lt0JjE1mzlqX6+GCopYNC\/Qh0KfNRT01g05chQNktmINtdshYfT7mt46BS1rWu1k5L83C4r1SJ4BNLaUCOn4M7xAJQIy3ziaUAYGuBxH3Cv6S\/lrslN+VrozKTTeXeGF4YVNxo6cOjx3AR3niNukENuZVGr5mfBAVocodMmbeaiqhh9MbXK4sEqXIRwWpBCzvIfkej1Rt73iFDjyW2glon2aiGaYYygjaEX1UArplXUqF3CvoPbK7Q84q0l3vEkmfOmYonrQq9mPuZSAMBLufMhJ1M9FWq25L\/O7vvB+6AJVBpFRazgBgKiB3VD68l0bHvINIeMjkYFV58Ek1u4VMyK80IKfVlrzzEzxJ8rD\/aVjt1THHwroyF+gMUByxlQVFx0D3xidzVzMr3g6yfmL01LaO4NjTXbXgXEbr2elLnLf4IfEG+MNq8XWMZIIz2S5lceL2tb2XEpPVEhbKP\/HVuwFKOh9YNMOtDhbsmg\/d4Yh7SbJBvHi2LxvBdJ9LAFKxYTUnknnA9pKNJszuDXGWsvZg9jS4UW2RvLIz4nJbYrSd+w9aiKs5ORtvUbp9sXYwAZdlkJa\/tux80yVJd9kSPVT6G52YoYGzv9PtRJWQzDWs+\/m1qkr0W1PNNPjOaMb15WBTy5RVkjeXUgVHUVluln7lVFECG6gwJn51j0jE4HMBWhgPiGXwN4WWFLCgt+CDnnbHbUeb4atuNatkcmj6l96\/BXO7kSCue9yWKde7qxZH0ZHm+mdFvJMhif61t6q1j\/4ZKsv82pf2ar\/M9g4vDPOu8p4Uk1qfRKQpPQkyKUN4bOWH7CMn1vTYkl\/tQjKUN3uCeSQVOgTAP5fbnZuN9KGaJYef+d8khqQFqqN6EW35E\/scDG9p6YUdXWNAX0dmOIx2cb5KoOLA4e0\/SANkBFt0FPozPtEPB0OUa40myp860VhexWoTqBAy3+JywGdZuCCPxrzY0CrjlERXI\/Ji8mwLkAVqSdG4PtxbHVzAKLkhZ35mXtTGUY6ZCvY8\/mhYjZjj3+ZpDodw9vrEplhFG\/VeVWZTFOA9HU9nLPpIQcQatfIF9bh9gs7WXzxHHL0SskzVHhZDdNXRjoaPN3uto70DuE7XoPFKvCgKdyvpwi7e65LzVgWaVwKA4LiCTCGB0V97+xH7l5L5NHaln1gtA06RuVRK1t1KBiXYuPKQ5DDQTL60mM3wuytkq\/zfY7kmS0VQMyH+0X7Jm\/EYyyMaDiQ5jEBtDYkrdNwOLQYK1YHX8a\/IgG2Spgx8jd5bbfVD209yB\/Ie3XwIh9rOrZQYeFvqg6qfsiOsBNxBlcWgMmaovn3E+Ab+GgNfOuAo6fFiRClo4zmnSMPxp0+mpugB5rx9Bazn9+lXZlGDS8CCwrH0ZnScpgdm5LNoaPs\/MJ+UXL4iQXzalrCHA1UlZaMU4LjfQqq6ocOb4cTSmd20zAKJemfKDCDOCdTJf\/y6AhnQQHStqZxNCvdUbKyo\/f2lAglerksPYkFEajnO367CMgvwIVUtocuGbFElwKOIIK9ID123Z4GkgqA61rJmhI\/eiNzdwqeNFGqO94ETSsmlFMOdYeTPKhsWJzhv9wJTRyWEJMaGCpKBtP+3\/JFUB1wkkMCWF50H\/leM4U9ipXQPTImBlCWXdA84jpcoLb0BWtJCaGK5CgOPyX8RkDmJDsjPN2XTTnLg1D7Dhnw9Y8ldyJNHEilsr4weAbihSfqHAbvhd1aB+vq7F9slIOFBm5NIoQacN6obWklRuwvbF3XivXOhyV9vhYiSV+8+RY5X0CscB2vYtuXjJJYVwWPLCQd5Ayo\/Fi+wmOtC2HvYA68XX4jsJC0WwCy61kadbNw5BIELgA3jEKNYCHRDIDGjV0vUwbFJYU4O7skDdKqFpoxMUD\/2\/IqwajeLEJmFWSZwwsNPJwUU\/M5rJNNhj827KWZCILtm7c5aO\/PN3pLovhuLrDmw6qKXNT3DOQDy0B45WIznpzQhAQ6KbsPwd\/vlkH3iZ7xVd7cUYtB58lVovpt7I50NXlpUsaX4h40TXSa5bmhjrQU9QHO4t8LiA+rdkjMTKsUxu7WHv6356DQCSROgExGSptl0+i3An6oRN0gtRpmxDtVh6IcxGttZfV\/xLU\/lRlFueQ\/I1a6LMyhxbLuXc7De225\/SNih9I0BdLDUV8R5bp5z2wKKa15vJWAHxQ1akzd26FK0cfLA6NWnsHkA931xNOdtOw+ZxBCYggWa7ZQMkBrY4JUc\/mdDMXfH9hvgW2eKQRSUHAywsN29iaVFCsyBietsbduY67ANzb6QrK088W+5iPeKN4ACmOO\/5NPNeAXdIl2MZTN2kwNPMvC\/01hUQXLboHzb3fML3L10PbOCnlWAiui48xHJFLjSGv459rjj7P8DwETd8p\/9IagPpBMWAEgkz97sX1heWJeAGLz7GEmNYfDWSQHS2QWqyyAT+isKHZBA7GqekL9h3EHSfKv947uzvdMHQz\/nF9DZ3kqbnKiRd0k9y6LD39jR3EJE2\/6Hl5f6UD4i5rn9jaheQvTk0vVSmR6EhUXim+h6uAsTK6lSqDVFXAmMAZomdmu\/YG7wyqFNV3UIbh9F7eph70d7222VLH7MwDrZyKrDIIvWu2GTcSM0kTwrFZWCSoPgDn0GJ9WkZteAlJgRaI1u0vK12s3kcV76BprOYsnb74hNNk5lBVQ99zzgQ284iF+U8Oxb+ILGHiPlIb6HZ5shdL49jwMEwIBDl8avalU+A9oYeMLBZtNJxiaktg+I2f3P4BoBD6cvcRn+Uj31bzJGssVIe2+hmcIYqoTTS7anumAHBf6IxRDXXTiERSf\/om39lMBXZ44lIdcq9H8AmREqX0ass9SZURwDLTKKCGqMfGBIIx7wTlhu+OGknPLkQWGZC6v16LNWQeRYLJ9Mc+X2HKsANHtzYvrOPInAWmZ5n5kpS6Ph54SZ8MjW\/s2ENs326ej9MkXzLB56ZvrQhkWanmvmsH4V8cDC4R43Ju5vgpFUWlVYMk3bfSpUgT8LL5GLkAfuGNfDTnAucWI7jdquXn\/g8x0mUhavZUpq28hp\/gedXiGBRIHM1SWkM1Prm8rfkdM2BfFYsLLmw2kOn05BoZZXn7L7bj7zeAr+PnY\/42rgdrTDj9MSU0TwsrIzhBShOfWfXhrySOhYyT9vpT7wqXq2hKh39YMZzERuAdWlySGUoSt0n4oIF5ruFuKrBviuDZ2Fww6XYTgEXhs3O6oYHCNMxhkUHc6jORJ4\/w1nZ3\/rDGmGxNoX7bkDvxCNr80+pT5Ld5LHrLbkTR1RDuLUMyaEvS2jFAoWgIcERoQaXeZpLPRDheGaO2\/\/gVSYPrPc6n13C0sRqYOLnfLsz1YfJb5Jsi05dZq\/vvcx4zzbfFdIrz0gKG7NN7vdhPLVX1g\/xaG7NEFIsMCoCPeHnm3fgv\/HN6JbqgjMa7HgdIMXZcGvqkFlCnRTdvzzxrgM6lXbYgl\/kaXPsZxaw\/2BDZ\/aGAfufiIMO7gssq2iUhIYJaFNX5PTlDRN7ez85DVC6zn3b8w4VbFJiTc7DpP1m5CQHhK6BC8tBlLZwBRqvCvApIZc9I5yddRIUMBCmm1ArzCNZ+c7ZfLT2o\/5pIU3GfxJj7LvltgweKfLfJnYz9dcP\/liN3z4ajdzA\/+yS9p2SCJh4mQUB27RqDkz1NeANZM1NLbRWxlTJHIZsl9+j0I85jZfKpd5uZjDaZlsvbRzHPam1+u\/zww64MWY2AVfeT+nS+jXHKqjkhc44ueBZX\/brprMlI+1sYSWBkU6jJryA5vyFo7rx2edrmr8Xnb9ohl8ZcWEjVllPaa3FDrLihi4FoZCiHkO+xvQGuPqua7pG+RaoJb7AGXEkOU8KWvOnlFVeyhB5bXtvCVjhvLJyLATKbpXkT2jd6ZY71+EYCAMV7a3+U4+FsRvCL5NE6WlcPYVpDwFGi9UV6ypmltrCHTY8kDdHxcVOPr0ByjjMyTj3leGeSdb4\/e+212e7QxgH2L95HCWxrxC0l\/PMfc6hf98F\/YM8sLEGcURf5ccRp1ZcdaERotmRThQw1w6HXBnxpKSH+ZxUJXrHjwLf9pIi2FZWCooSdfmojuD35dACxRAJpNuE7hKbGe+WEuLhvMzFTY5Ev1ayHzHhJnBwGzASWebejVxEJkvFnmf1pblmCMtsTCv\/ZKaLA07HIFAFE1FKZM\/6xmcD8wtziP4NHepWtyGAXXyDrTCjVY5oi6VQgx6mWZBH03DA+X71SCoLOA0qpbzDbArz0qrWZZsLodEHoWWHM6IHMR3TmIGwF0SGn2EKXUUgcYgE4429joAvCsRKIYtRy32MfnhOZcVIb7b3+z+7nKERLadtZdnC7xfwMF902pCyXh9x4e0QXDq4F0zFPYZxWgvxZLiH25zmbohH7a2NQOs+q8Ib46QbHCTvRtKbdwfvR9PyWwRahSyP1TxA1qseFW7NBTRCSdi8gt9jxdc25\/sBlUFs12bM2wJHiyelfO2IPc1Fn23rLFvk1J2PAEj107v\/i7sbyJYgbVcIEN3ir7OoiLN2oG2OXLynTDx89DDGDLYMmWQSujnWSXCHJK5kEN+W4Rwa0yzf6pnlL8\/pkOd+TwgqbGVsA5tx8C38VCiofE8Zk83u1x3KiImtiAKVjjln0ezS\/s7sxxYSIeSRxChQ9rPN2KV+gR5kGbjYaak+uvevXsg1R0RKKWXxUDq1i3FQvgnFCbbPpiJJB3ViPp+uQ0RTY01rayZ5EtZ2qa+pPxcUXQv2WW+XFKUA6LmCfqsieQGayaRFwg0c5NoKkJD1esdE1efPj3YmlCNFS\/KqPhNZX5+N73R\/BoETxltynUp+mTG4qCimINNp133DDbdCGJ9MkiY9wcPYEAmcqnOhmtdz3WN2P19i1xNLQ98i30pNcQlwoGkuSpKK5o42lI7bYQIFofuRTpkETPE6YL80MUH3zOWfpT\/08RQwyvhVfft4IBxKTT+j046yvpV11uCGE9c\/4tiI+JsCkl1WpEUuHEj\/UBervkn+V112iT6zvIjW\/L24mf3S8MvxZNz+XK3d20qANQsAvs0XDvd49EveSsHQAV9Lxhlwd1eQ1p46gWagw3KckRKRPbH48+9nDh5SOLPYDfcAOd8TgEbh\/OVawlDM7r86XY2IzGhqpNAp6XELjo7vRItHwF6jiqpIldFJf2rGpGckj0ZN2gaa71WepDIaZuEy\/3ly+qj2LfYbPCgjYlTWNHk4DsU8a\/G4kCznNQlREXT9gsQ2aSzHsg7S+cDAC7UcNdnV+n21Gyo1l3KqmV4e2ZcvBnzifp2fEYotN3jCpx\/PZBO23SuGKuWrLG5bX87kQNIwBwjgpQWewKiLJiONybJc62C7wMntqFRnyFa7YEBXzd7ZAH2PzFqEs6sG\/AKqhvZyLYDD3ya9m2\/kwB7Vco1cMVop\/ePGy7rBNPWOv2W7Pcf3OtH+nAmgHdT1u6gAV0zh5iPnFNkOTwvgsTHA7woaLzFDPWC7BNZ\/mLjX64QB\/TYV5h\/OXEEEun0\/wwVeFat0UWtn3lfJkiEXwnLYAYl9fr5iFGHRGATg8A\/qn\/6BUFacEibREjwAfEptUyPyaD91y1cBjDohN\/fDWvHto3ULJrYuZVooZb0QxXq7e9PUtqxwzYrOMXnEiLHHTk5G+S47fNwMUJbfESRNV2QujrFGJrrN6nFnGZ6UYeMHtkyWryUW7Vky1AnVGDVsLzsSFtiwimWw0g4nIk2J3WmF1oy7dzUbpvtiVLQwuHjVzjn4mJ21lR6IseRKrM6z18NWtO9hMzZwFXytwTQA8flozcNIuPBHMX+xjMNgoUQRNDRy3LID6N\/kEzBmeFRfXscplpMok16VbuI7huJd1J1ucAOgNLNkN6o20vWEg7Wzn4iRssVYHd8zT6fGqnLrcRavyJtSn9Y\/6xot7+80\/il2dEnMIMhJ6yVhGR8rclWcgbhmuNuhKIWmageZ8\/P7W8LPRzX\/KmiWuqCiLXNYDwdnq2V441WprD8fEOrZHwLIllpnNZUGkUj9RC9\/q016ZWoLJI3LdZZDUbGltu6bXn4CsmeQaSHPdTm7KtqyNPmJwrHJam9lHhnE691uappj7QFFk9OjVUumOnPX0CrIAnZNuWY2WI9CNuAuhlqtJ5qMvJDNYV\/0+v\/Q5IjQKV4RbXbPWZO5cnXCtNfSV1AKaD+H7OWfun\/vRlrwfujOdyeBvMpdPT31EL0aWtnQoU7Z0L3yP9d9Hiws1of6vLeMQaIAqOZVofJ240VU9k8122P6IRHtg4e5hjLe4HvmMFaPPUCLWgAkjC4Txnbt+ZbN96LLX4z4clO52K1pBMeRJgdz6WQp6bL1YozaspzNlIz4Pw9O2k8O2U+cVBqthbrD86zHK7kgA0fssaUvTFJIWls5JFSFmyWu722F\/KcG9YutdCbVloUOBKwBhmFUt1EfqGDDXf5NoqQPF2K7WRZemUUQU8w=","iv":"d478628f6139e57f76b948e2762e1b21","s":"09e13444ac3751db"}

Luxury manufacturing could be simplified in the coming years with the use of new technology. Image credit: BMW

Luxury manufacturing could be simplified in the coming years with the use of new technology. Image credit: BMW  The automaton can complete tasks with human-equivalent strength and precision. Image credit: BMW

The automaton can complete tasks with human-equivalent strength and precision. Image credit: BMW